Home » Industries » Rail Transportation

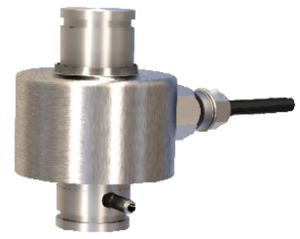

The rail transport industry was one of the first industries to use load cell weighing technology over 50 years ago. Traditionally this was the most efficient way to transport raw materials and products across the United States that were too heavy for truck hauling. Weighing rail cars that weigh hundreds of thousands of pounds has always been a difficult application. However, canisters and insert sensors are designed to take this type of abuse allowing for many years of maintenance free operation.

Case Study

Group Four assisted in the design of an in-motion weighing system for the railroad industry. In-motion weighing is a very cost efficient system to measure rail car weight. This system eliminates the time-consuming method of uncoupling a rail car to measure its weight on an inactive rail. The in-motion systems measures weight as the rail car rolls over the weigh-bridge load cell. Group Four designed a special insert sensor for the bridge to accurately and quickly measure rail car weight. We also had to design the insert senor to meet all environmental challenges for this industry. This design saves railroad companies a great deal of time and costs. Group Four is proud to be a part of the solution.

Product Groups

Digital

Description >

Our digital load cells are ideal for connecting your weighing or force measurement application directly to a computer, DAS, HMI, or your proprietary controls.

Double Ended Beams

Description >

Group Four Double Ended Beam designs are basically two single-ended beams back-to-back in a single body to provide low profile solutions.

Instrumentation

Description >

Our Instrumentation products include digital weigh indicators, process instrumentation, handheld indicators, signal conditioners and wireless.

Rocker Column

Description >

Our Rocker Column Load Cells are designed to use less material and easier to apply sealing technology.

Shear Beam

Description >

Our Shear Beam Load Cell family offers a variety of solutions for low profile scale applications.